Research

About Our Research

Recognizing the significant impact of occupational aerosols, including welding fume particles, nanoparticles, and bioaerosols, on air quality and human health, it is crucial to assess exposure levels and implement control measures for mitigation. Thus, our research objectives are centered on controlling aerosols to both evaluate and improve air quality.

Ongoing Studies

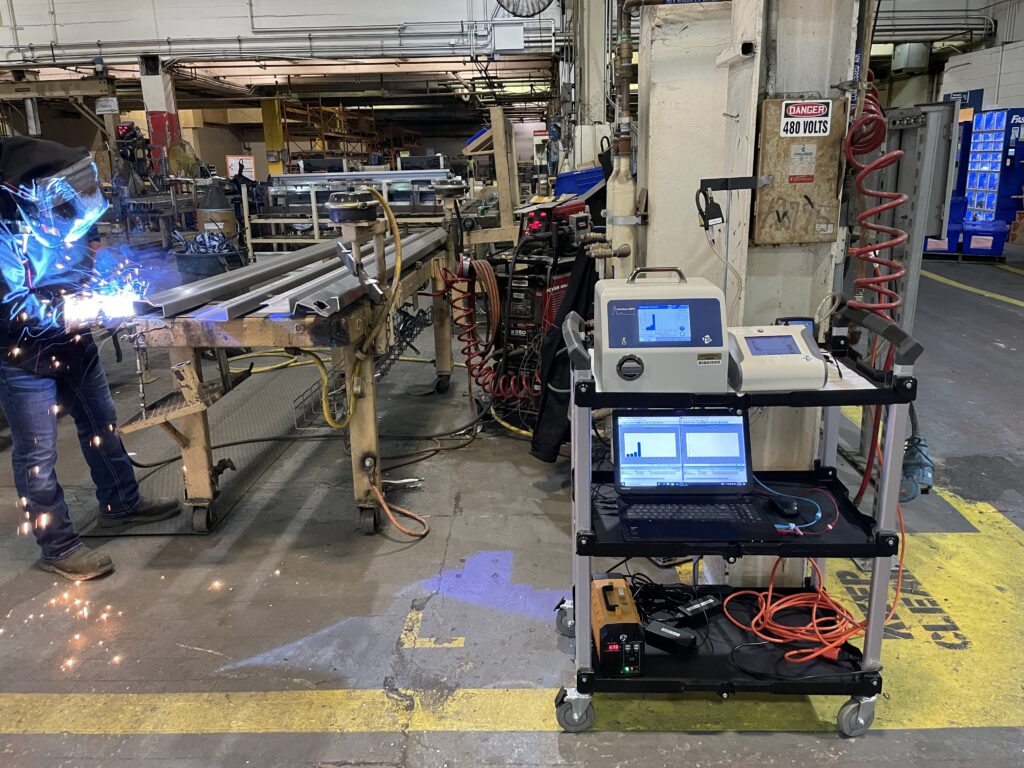

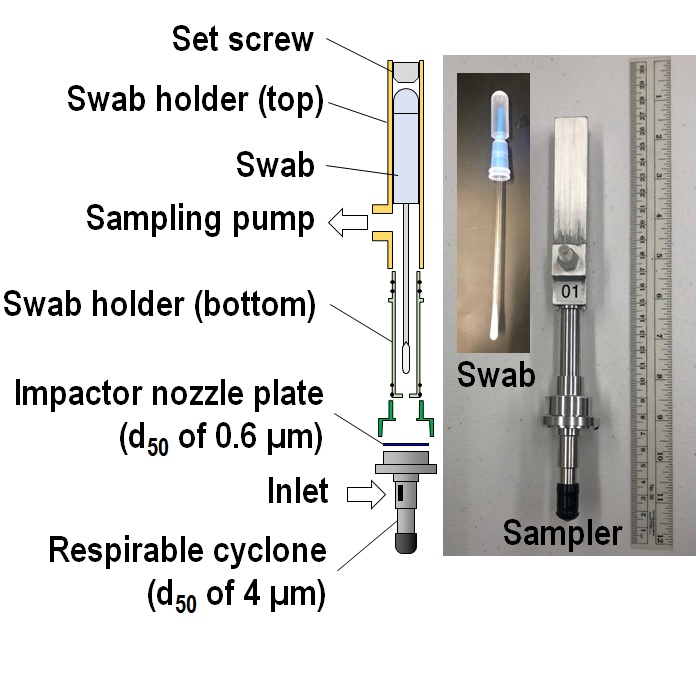

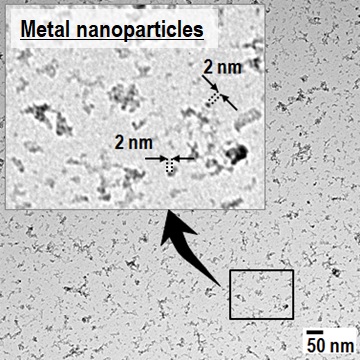

Assessment of welders’ exposure to metallic nanoparticles

This study aims to assess welders’ exposure to metallic nanoparticles, including hazardous metals such as manganese (Mn), commonly found in welding fumes. Exposure to Mn among welders has been associated with Parkinsonian syndrome. Despite the presence of various metals in welding fumes, current exposure limits primarily focus on larger particles such as inhalable and respirable particles, overlooking nanoparticles’ significant contribution. To address this, the study utilizes a nanoparticle respiratory deposition (NRD) sampler to measure welders’ exposure to metallic nanoparticles comprehensively. The study, conducted at a local manufacturing facility, aims to evaluate exposure levels across different welding types, providing insights into occupational health risks associated with metallic nanoparticle exposure in welding environments.

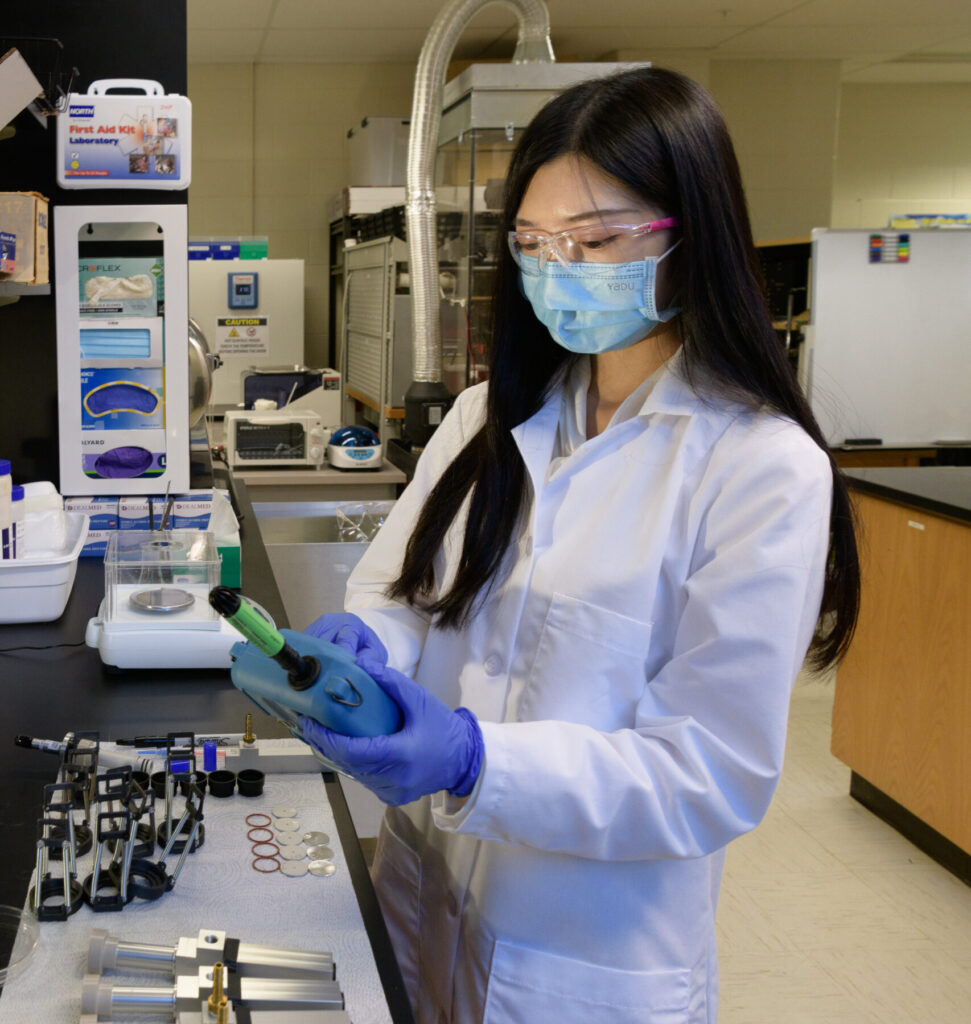

Development of bioaerosol samplers combined with various analysis methods

Bioaerosols, which originate from biological sources like airborne bacteria, fungi, fungal spores, and pollen, can lead to various adverse health effects, including infectious diseases. Sampling bioaerosols is crucial for assessing exposure, identifying sources, and controlling air quality. While traditional culture-based colony counting methods have been commonly used for bioaerosol monitoring, their 24-hour colony formation time renders them impractical for field applications. To overcome this limitation, we have developed various bioaerosol samplers integrated with non-culture methods such as adenosine triphosphate (ATP) bioluminescence assay, immunochromatographic assay, and electrochemical sensors, facilitating rapid and on-site bioaerosol analysis.

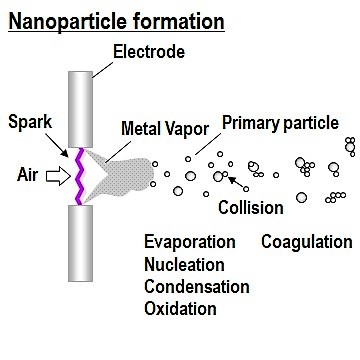

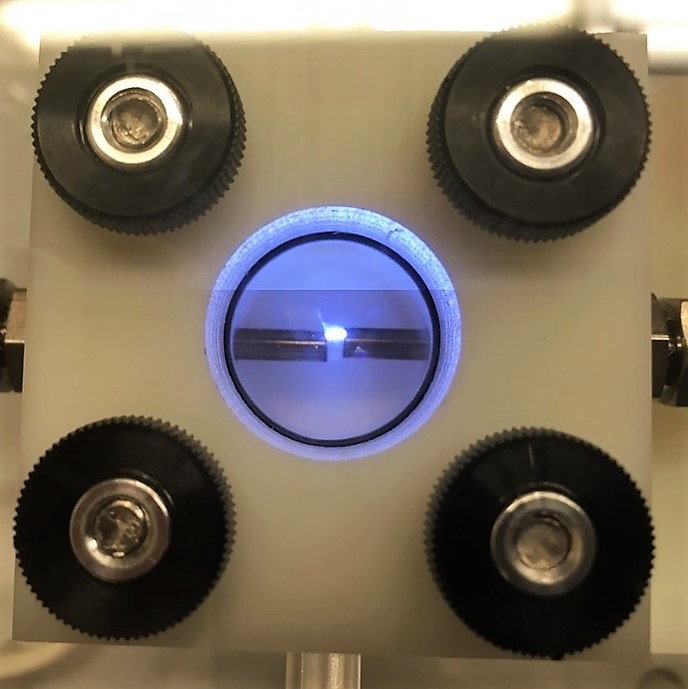

Synthesis of metallic nanoparticles to simulate occupational exposures for toxicity assessment

This research focuses on synthesizing aerosol nanoparticles for toxicity testing, utilizing a spark discharge system developed in our laboratory. This system facilitates the generation of metallic nanoparticles and has been applied across various studies. During operation, a spark discharge formed between two metal electrodes vaporizes electrode materials from their surfaces. Subsequently, metallic nanoparticles form through nucleation and condensation of the metal vapor. Importantly, the spark discharge system allows for easy modulation of nanoparticle size, shape, and concentration. Presently, we have utilized this system to simulate nanoparticles found in metal fumes, generating copper, stainless steel, and welding nanoparticles. These nanoparticles have been employed in toxicological studies, respirator testing, and the evaluation of instrumentation.

Development of a method to monitor particulate matter emissions from concentrated animal feeding operations (CAFOs)

This study focuses on the development of a method to monitor particulate matter emissions from CAFOs. These operations are known to produce significant amounts of particulate matter, which can have adverse effects on air quality and human health. The method being developed aims to accurately measure and quantify these emissions, providing valuable data for regulatory compliance and environmental management. By implementing this method, researchers seek to better understand the impact of CAFOs on air quality and public health, ultimately contributing to more effective mitigation strategies and sustainable agricultural practices.